Description

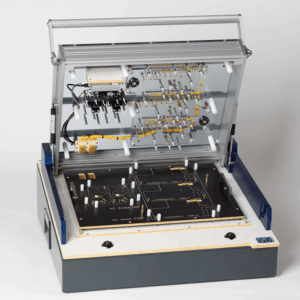

CNC Turning Solutions for Compact Components

At SJ CNC, we excel in CNC turning services tailored for small, precision-engineered mechanical parts. Our extensive experience in crafting machine components, jigs, and custom fixtures drives our commitment to delivering exceptional results that align with your specific requirements.

Our advanced facility is equipped with cutting-edge machinery, allowing us to efficiently manage large-scale production while maintaining exceptional precision throughout the machining process. We offer personalized support for clients needing specialized components in limited quantities, alongside the capacity to fulfill bulk orders for thousands of parts with maximum efficiency.

Technical Details

- Process: CNC turning for compact components

- Material: Steel

- Heat Treatment: 30HRC

- Precision: ±0.01mm

- Machining Steps: Rough turning → Threading → Heat treatment → Finish turning

Benefits of CNC Turning for Small Parts

✅ Exceptional Durability & Hardness

- Employs robust materials such as stainless steel, aluminum, and hardened steel.

- Provides outstanding wear resistance and withstands high-temperature environments.

✅ Enhanced Aesthetics

- Yields components with smooth finishes and exceptional uniformity.

- Ensures high precision with minimal discrepancies among parts.

✅ Cost-Effectiveness

- Bulk production significantly reduces per-unit costs.

- Automated CNC processes minimize material waste, lowering overall expenditures.

✅ Designed for Mass Production

- Ideal for generating thousands of identical small parts simultaneously.

- Maintains consistent quality and precision across the manufacturing process.

Our CNC Turning Workflow at SJ CNC

Step 1: Understanding Customer Needs

- Collect specifications, dimensions, and material selections.

Step 2: Consultation & Pricing

- Our knowledgeable team provides design recommendations and cost estimates based on your technical needs.

Step 3: CNC Programming & Machining

- Detailed planning for production, machine assignment, and workforce management.

Step 4: Quality Assurance & Inspection

- Perform prototype testing and comprehensive quality assessments before full-scale production.

Step 5: Product Delivery

- Guarantee timely shipment of high-precision machined components, meeting all customer specifications.

Why Partner with SJ CNC?

- Specialized expertise in high-precision CNC machining.

- Utilization of advanced CNC lathe technology for superior accuracy.

- Flexible manufacturing options for both small and large-scale orders.

- Competitive pricing without compromising on quality.

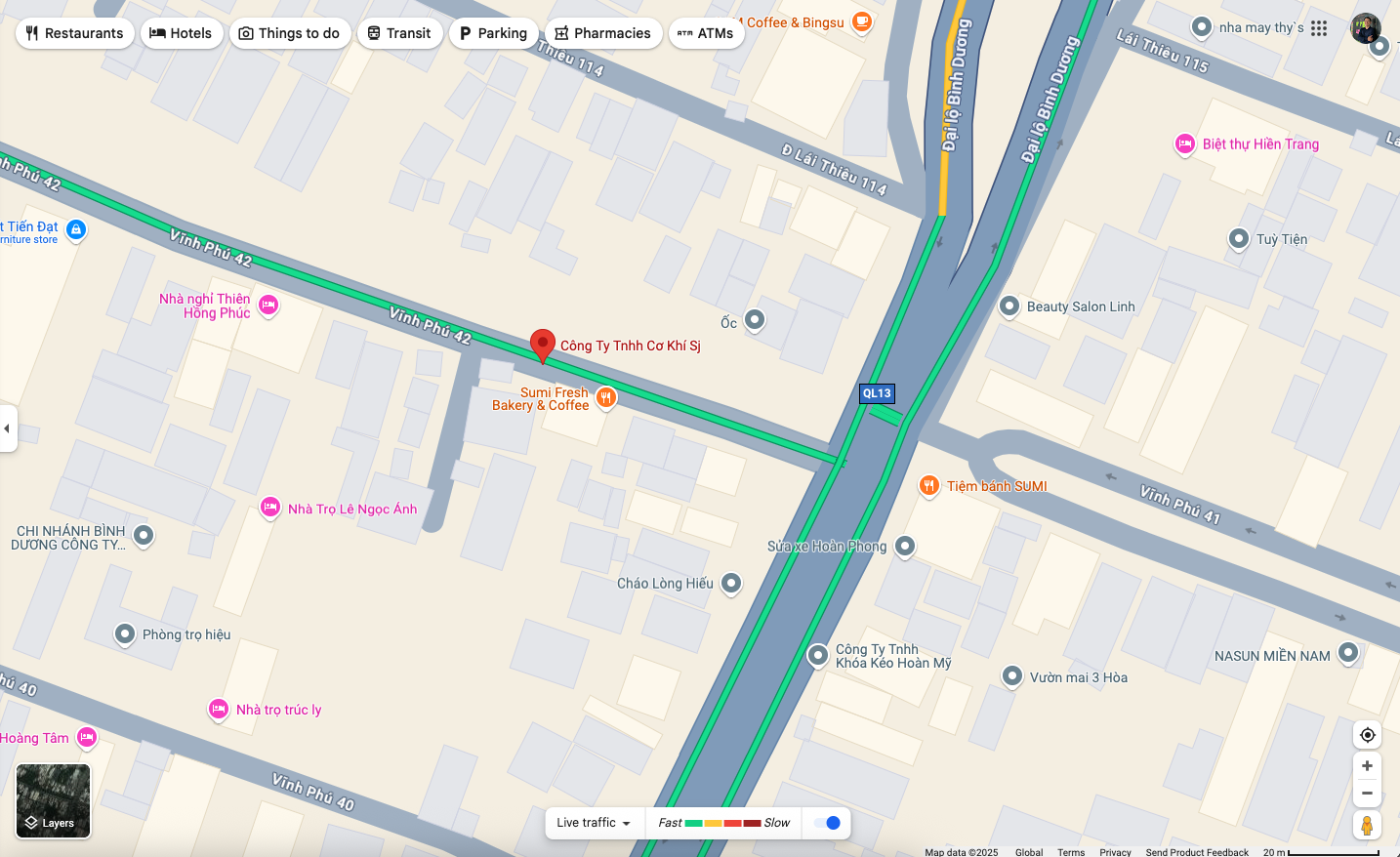

Contact Us for Your CNC Turning Needs!

SJ CNC specializes in precision-engineered CNC-turned components for industries that demand excellence in accuracy and efficiency. Reach out to us today to discuss your machining projects!

Reviews

There are no reviews yet.