Description

Understanding Inspection Jigs

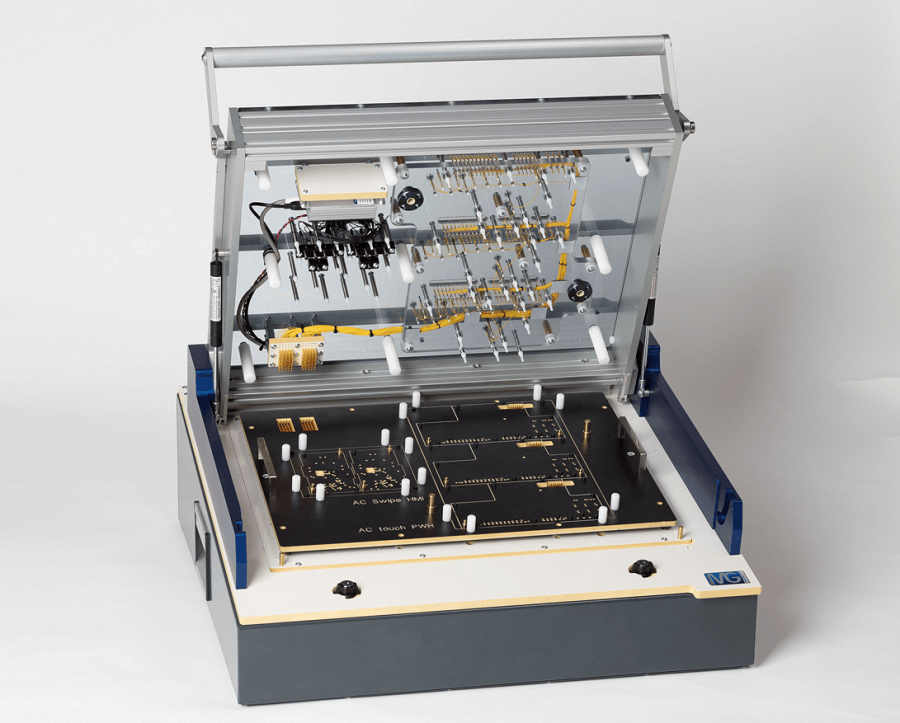

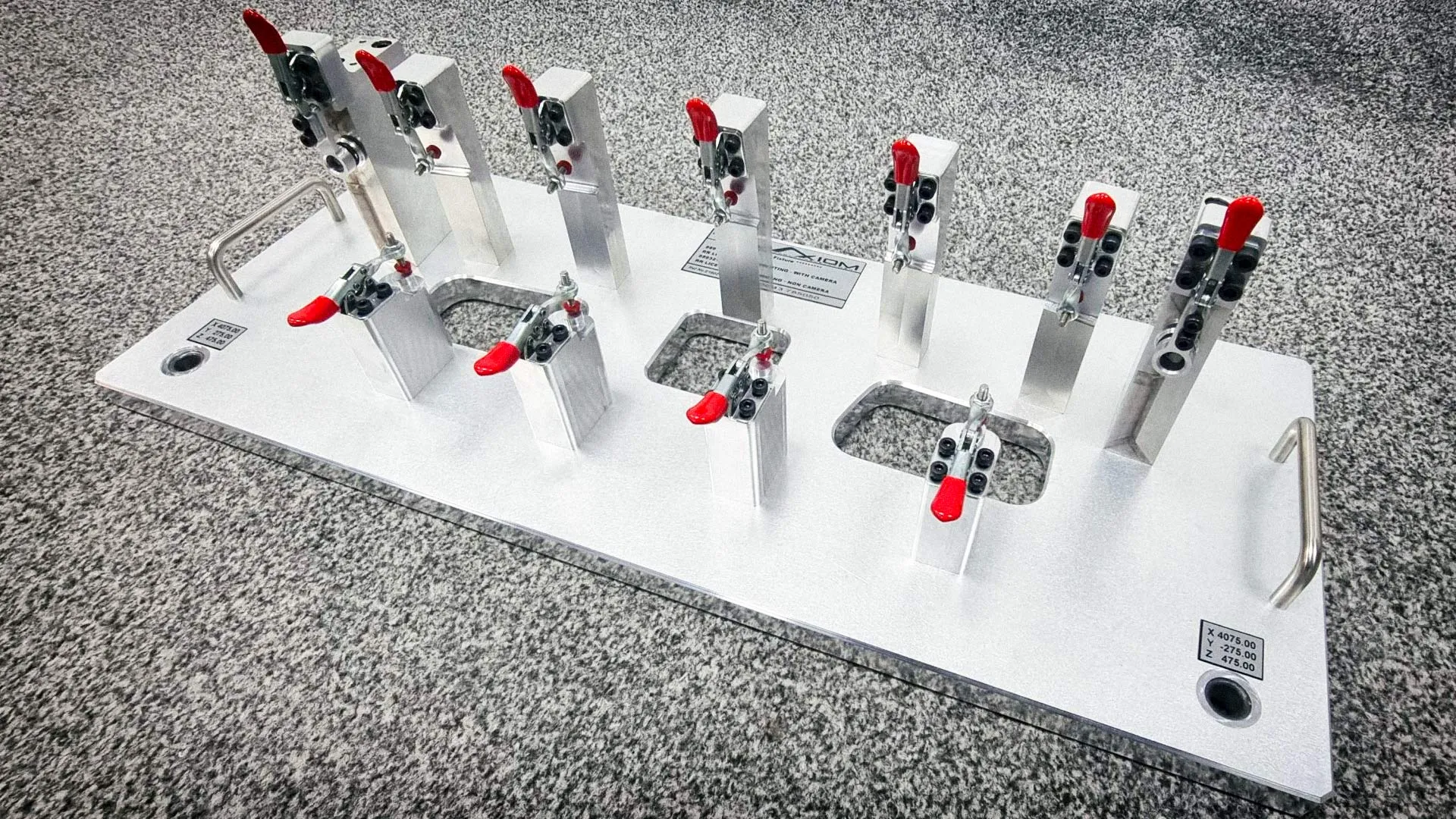

An inspection jig is a specialized tool designed to assess the precision, dimensions, and overall quality of products during manufacturing and assembly. It plays a crucial role in confirming that every component adheres to quality control benchmarks prior to mass production.

Expertise in Inspection Jig Design & Manufacturing

At SJ CNC, we excel in crafting high-precision inspection jigs tailored for sectors like automotive, mechanical engineering, and electronics. Our solutions are specifically tailored to fulfill client requirements, guaranteeing exceptional accuracy and streamlined quality control procedures.

Leveraging years of experience in automated inspection technologies, we deliver multi-functional, precise jigs designed to enhance manufacturing productivity.

Components of an Inspection Jig

Inspection jigs are available in various configurations based on specific testing needs, such as dimension measurement jigs, profile inspection jigs, and surface quality control jigs. However, they universally consist of these key elements:

- Base Frame – Offers a solid foundation.

- Positioning Mechanism – Guarantees accurate alignment of the test piece.

- Clamping System – Secures the product firmly in position.

- Measurement & Inspection Mechanism – Comprises sensors, gauges, or other testing instruments.

- Additional Components – Tailored to specific inspection requirements.

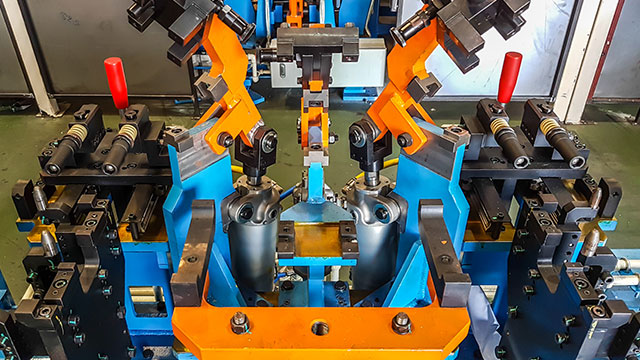

The Importance of Inspection Jigs

- Ensures Precise Quality Control – Accurately measures and assesses product dimensions against set specifications.

- Reduces Inspection Duration – Automated and semi-automated jigs expedite the quality control process.

- Boosts Manufacturing Efficiency – Detects defective components early, reducing production waste.

- Customizable for Diverse Testing Needs – Suitable for flatness, concentricity, friction testing, fatigue testing, static load testing, and dynamic load testing relevant to automotive and electronic parts.

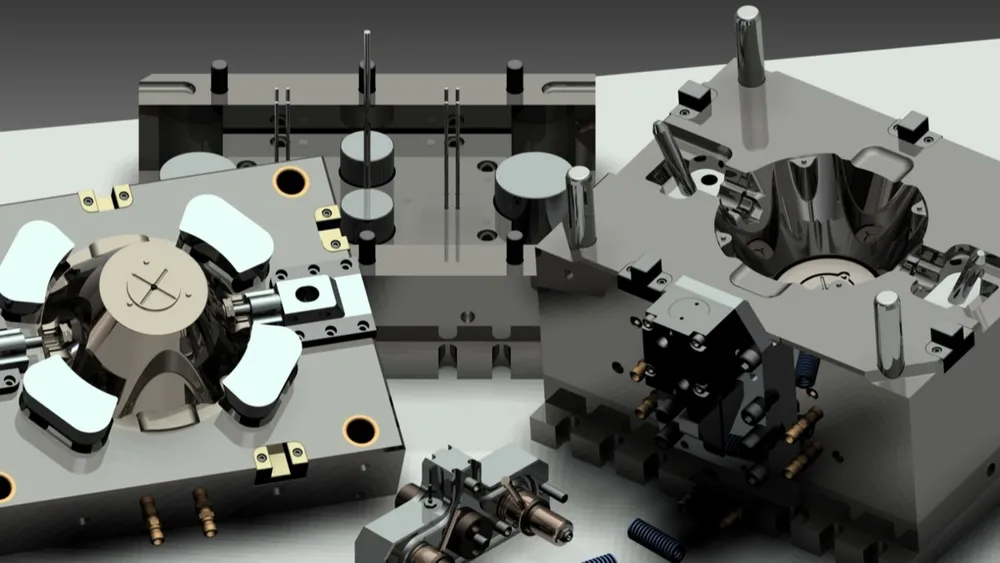

Benefits of SJ CNC’s Inspection Jigs

✅ High Precision & Reliable Results – Engineered with state-of-the-art sensors and measurement tools from Europe and Japan.

✅ Fast & User-Friendly Operation – Facilitates quick part insertion and removal, adaptable to various product designs.

✅ Durable & Sturdy Construction – Designed to endure forces encountered during testing and quality checks.

✅ Seamless Integration with Automated Systems – Compatible with robotic arms, feeding systems, and digital measurement displays for real-time quality control.

✅ Optimized for Unique Environments – Employs wear-resistant, heat-resistant, and moisture-resistant materials for long-lasting reliability.

Why Opt for SJ CNC for Your Inspection Jig Needs?

Our inspection jigs are 3D modeled and optimized before manufacturing, ensuring ease of operation, robustness, and unmatched accuracy. We provide:

- Custom inspection jigs tailored for various quality control scenarios.

- Advanced automation solutions for efficient quality control procedures.

- Dependable delivery & cost-effective options customized to meet industry demands.

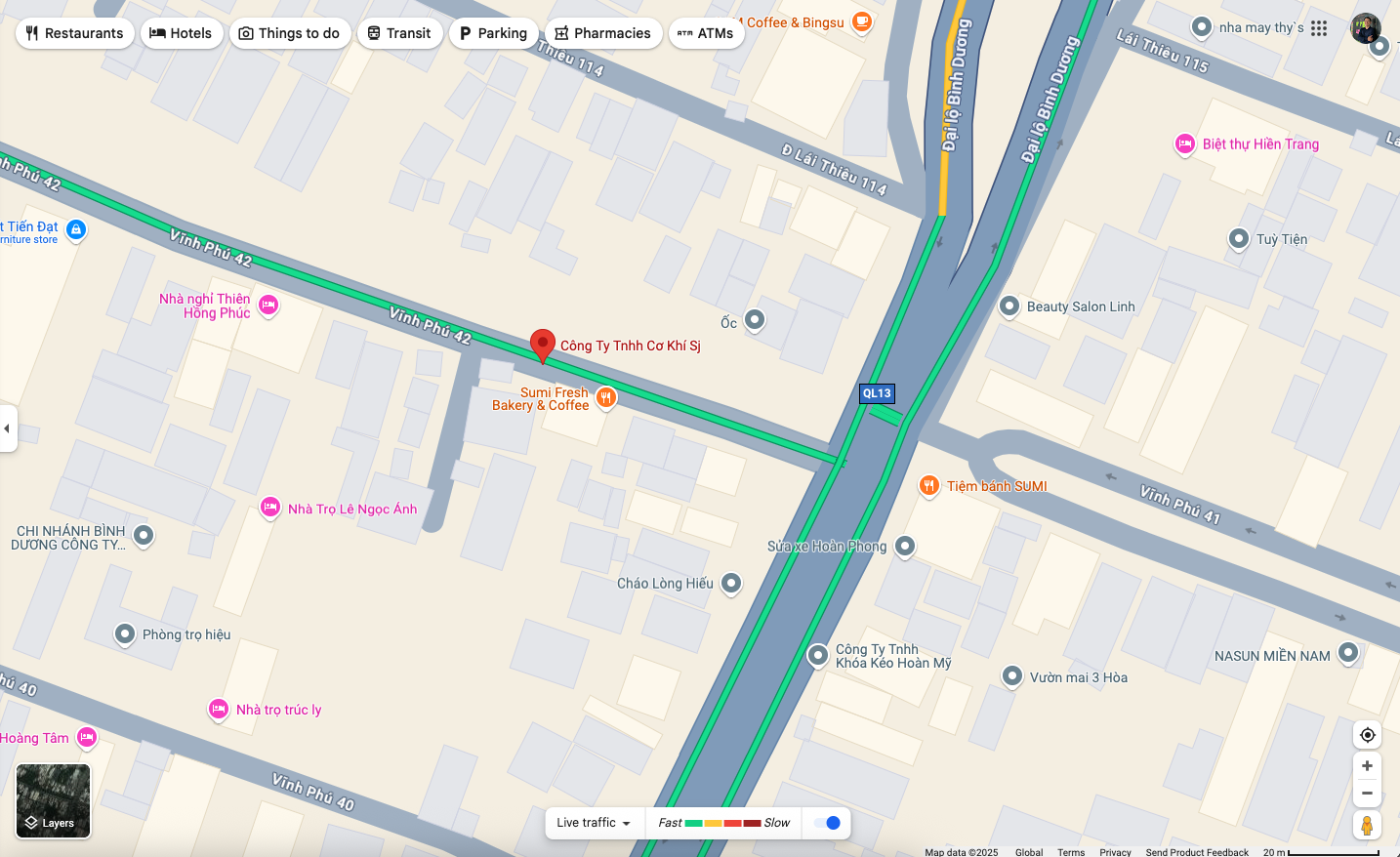

Contact us today for precision inspection jig manufacturing solutions!

Reviews

There are no reviews yet.