Description

Technical Specifications:

- Material: A5052 Aluminum

- Precision: ±0.01mm

- Surface Treatment: Gold anodizing + sandblasting

- Machining Process:

- Anodizing

- Profile Milling

- Sandblasting

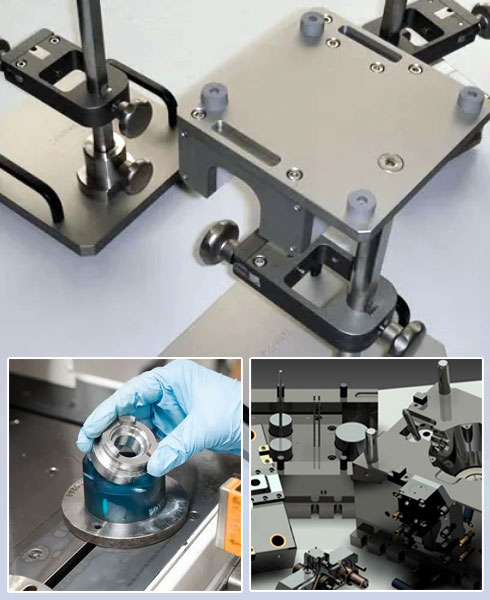

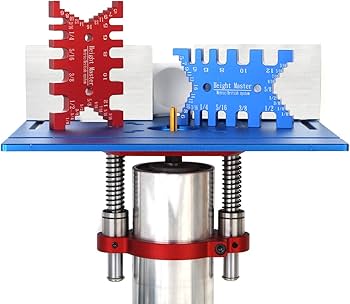

What is Jig Machining?

Jig machining involves creating fixtures or tooling aids that are crucial for mechanical processing, quality inspection, and assembly in the mechanical, electrical, and electronic sectors. Jigs play a vital role in ensuring product accuracy, such as checking the alignment of logos on phone cases, positioning parts for precise testing, or assembling components for quality evaluation.

Benefits of Using Jigs in Mass Production

- Streamlines Manufacturing: Simplifies machining steps and pre-establishes measurement and design strategies prior to production.

- Enhances Accuracy: Guarantees precise workpiece positioning without the need for manual adjustments.

- Consistent Quality: Ensures uniformity in mass production, making sure parts meet a variety of assembly standards.

- Reduces Inspection Costs: Lowers quality control expenses and minimizes material waste.

- Improves Efficiency & Cost Savings: Increases productivity while decreasing operational costs.

At SJ CNC, we specialize in custom aluminum jig machining, providing a range of designs tailored to meet your production requirements.

Aluminum Jig Machining Process

1. Workpiece Preparation

- When machining aluminum components of varying thicknesses, it is essential to control the heat factor to avoid material deformation.

- For complex designs with multiple cavities, machining should commence from the outer edges to distribute cutting forces and heat evenly.

2. Cutting Tool Selection

- Material Properties: Aluminum is soft and ductile, which can lead to material adhesion issues.

- Recommended Tools:

- 2-3 flute carbide end mills with a 45° helix angle for optimal chip evacuation.

- Coated or uncoated carbide tools based on the need for adhesion resistance.

- Cutting length should be less than 2.5 times the tool diameter for stability.

3. CNC Cutting Parameters

- Establish optimal feed rate, cutting speed, and depth of cut to balance performance and tool longevity.

- Minimize cutting depth while enhancing feed rate and spindle speed to decrease cutting force.

- Utilize climb milling for improved surface finish and reduced tool wear.

- Maintain continuous cooling to ensure temperature control.

- Employ CNC machines with spindle speeds exceeding 6000 RPM for optimal aluminum jig machining.

4. CNC Jig Machining Execution

Once tools and parameters are established, the CNC machine executes high-precision aluminum jig fabrication per pre-programmed instructions.

Why Choose SJ CNC for Aluminum Jig Machining?

✅ High Precision & Quality – ±0.01mm accuracy with superior surface treatment.

✅ Custom Solutions – Unique jig designs for various industrial needs.

✅ Advanced CNC Technology – State-of-the-art machining centers for reliable results.

✅ Competitive Pricing – Quality products at affordable rates.

✅ Reliable Delivery – Timely production with strict quality oversight.

Contact us today for expert aluminum jig machining solutions!

Reviews

There are no reviews yet.