Description

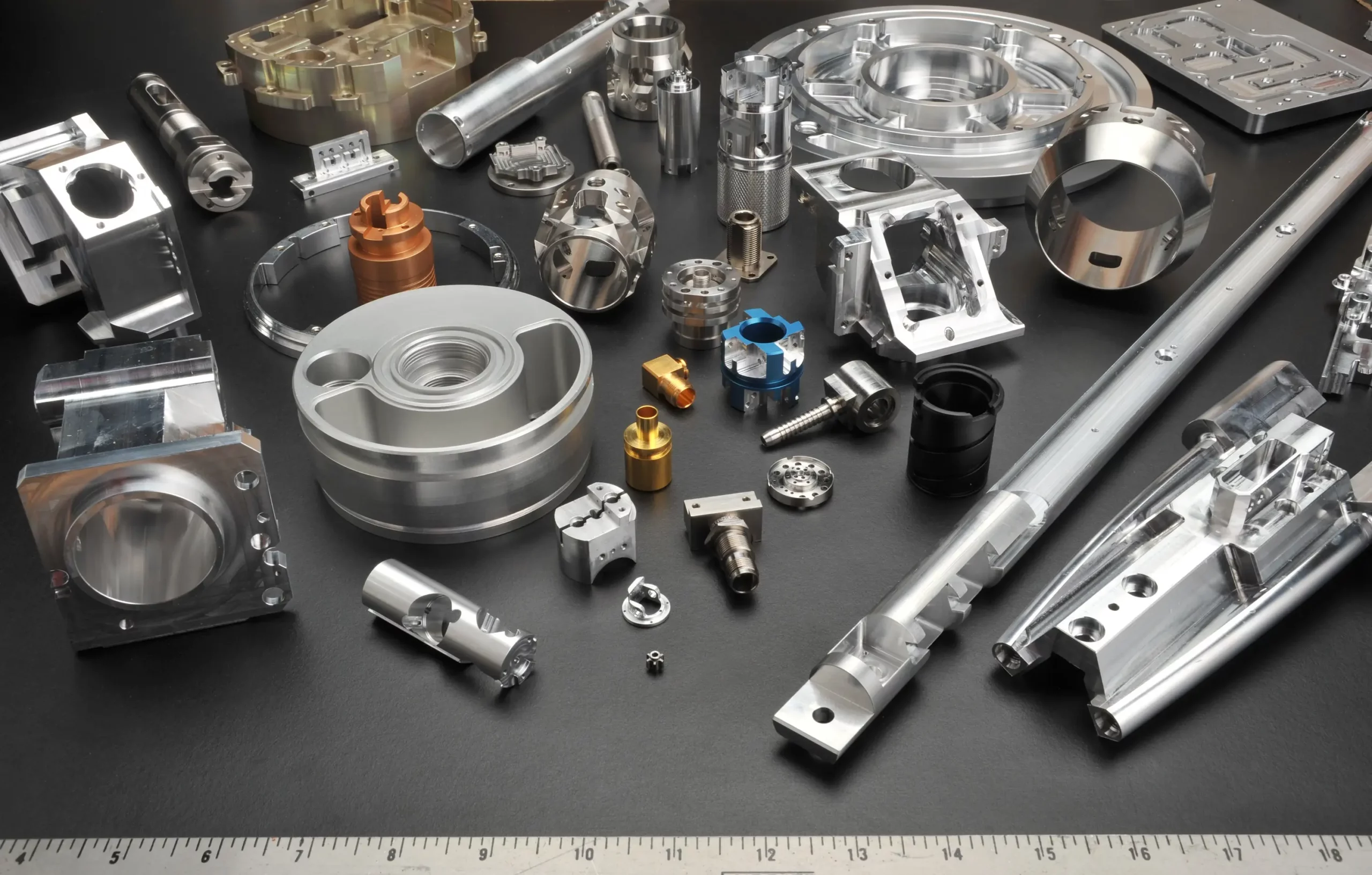

Precision Engineering for Motorcycle Spare Parts

Manufacturing motorcycle spare parts or other mechanical elements demands an extraordinary level of precision. This process is heavily reliant on cutting-edge machinery and tools, necessitating substantial investments from companies to uphold the rigorous standards of quality production.

Exceptional Quality Standards:

- Customer-Focused Approach: We place a premium on customer satisfaction, delivering high-quality products, expert services, and competitive pricing. We actively engage with our clients to enhance our offerings continuously.

- Expert Workforce: Our commitment to training and developing our team ensures that we have a skilled workforce dedicated to achieving optimal results.

- ISO 9001 Certification: We comply with ISO 9001 standards and are continually refining our management system to boost production and operational efficiency.

- Quality Control: Each product is subjected to stringent quality checks at every phase to guarantee that only the finest reaches our clients, fostering trust in our brand.

- Long-Term Collaborations: We engage genuinely with our suppliers, promoting mutual growth while prioritizing customer satisfaction.

Professional and Innovative Team

At SJ CNC, we take pride in our professional team, which includes management, technicians, and customer service personnel. With effective leadership, we ensure our operations run seamlessly. Our team’s expertise and years of experience result in meticulously crafted, high-quality motorcycle parts.

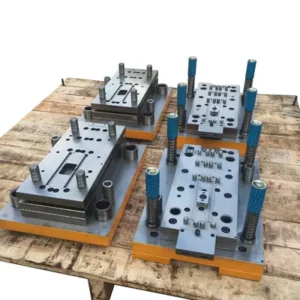

State-of-the-Art Equipment and Technology

Investing in advanced machinery is vital for producing top-quality motorcycle spare parts. Our utilization of cutting-edge CNC technology enables us to meet the demands for precision, speed, and efficiency. We are committed to continuously upgrading our equipment to align with both domestic and international market standards, particularly for export markets.

Motorcycle Spare Parts Manufacturing Process

Employing advanced CNC technology, we guarantee the utmost precision and efficiency. Our motorcycle spare parts manufacturing process includes the following stages:

- Understanding Customer Requirements: We begin by gathering comprehensive requirements from our customers to ensure we fully grasp their needs.

- Design and 3D Modeling: After collecting the necessary information, we develop detailed designs and 3D models to provide accurate specifications for machine operations.

- Material Selection: Based on customer specifications, we meticulously choose the raw materials for machining, adjusting machine settings for optimal outcomes.

- Machining: Each component undergoes precise machining using appropriate technology, following a strict process flow to ensure accuracy.

- Inspection and Packaging: Post-machining, parts are polished, ground, or sandblasted to refine precision. Comprehensive inspections are conducted prior to packaging and delivery of the final products.

Why Partner with SJ CNC for Motorcycle Parts Manufacturing?

With our meticulous processes and top-tier equipment, SJ CNC guarantees that every motorcycle spare part we produce adheres to the highest quality and precision standards. Our dedication to customer satisfaction and excellence establishes us as a reliable partner for all your machining requirements.

Reviews

There are no reviews yet.