Description

Expert CNC Turning Services for Small Components

At SJ CNC, we specialize in CNC turning, focusing on the production of small, high-precision mechanical components. With our wealth of experience in crafting machine parts, jigs, and custom fixtures, we assure top-notch manufacturing that aligns perfectly with our clients’ needs.

Equipped with cutting-edge machinery for large-volume production, we maximize both efficiency and accuracy in the machining process. We cater to clients seeking specialized components in limited runs while also adeptly handling bulk orders for thousands of pieces.

Technical Overview

- Method: CNC turning for compact parts

- Material: Steel

- Heat Treatment: 30HRC

- Precision: ±0.01mm

- Machining Phases: Rough turning → Threading → Heat treatment → Finish turning

Advantages of CNC Turning for Small Components

✅ Unmatched Durability & Hardness

- Employs robust materials like stainless steel, aluminum, and hardened steel.

- Resistant to wear and capable of withstanding high temperatures.

✅ Improved Aesthetics

- CNC turning produces parts with sleek surfaces and exceptional uniformity.

- Precision ensures minimal tolerances among components.

✅ Cost Efficiency

- Mass production significantly reduces unit costs.

- Automated CNC machining minimizes material waste, lowering overall costs.

✅ Ideal for High-Volume Production

- Designed for producing thousands of identical small parts in a single run.

- Ensures consistent quality and precision throughout the production cycle.

The CNC Turning Process at SJ CNC

Step 1: Understanding Client Needs

- Collecting specifications, dimensions, and material preferences.

Step 2: Consultation & Quotation

- Our experienced team provides design insights and cost estimates based on technical requirements.

Step 3: CNC Programming & Machining

- Thorough production planning, machine setup, and workforce coordination.

Step 4: Quality Assurance & Inspection

- Testing prototypes and conducting stringent quality checks prior to mass production.

Step 5: Product Shipment

- Prompt delivery of high-precision machined components, meeting all client specifications.

Why Partner with SJ CNC?

- Specialists in high-precision CNC machining.

- Utilizes cutting-edge CNC lathe technology for superior accuracy.

- Adaptable manufacturing solutions for both small and large volumes.

- Competitive pricing while maintaining high standards of quality.

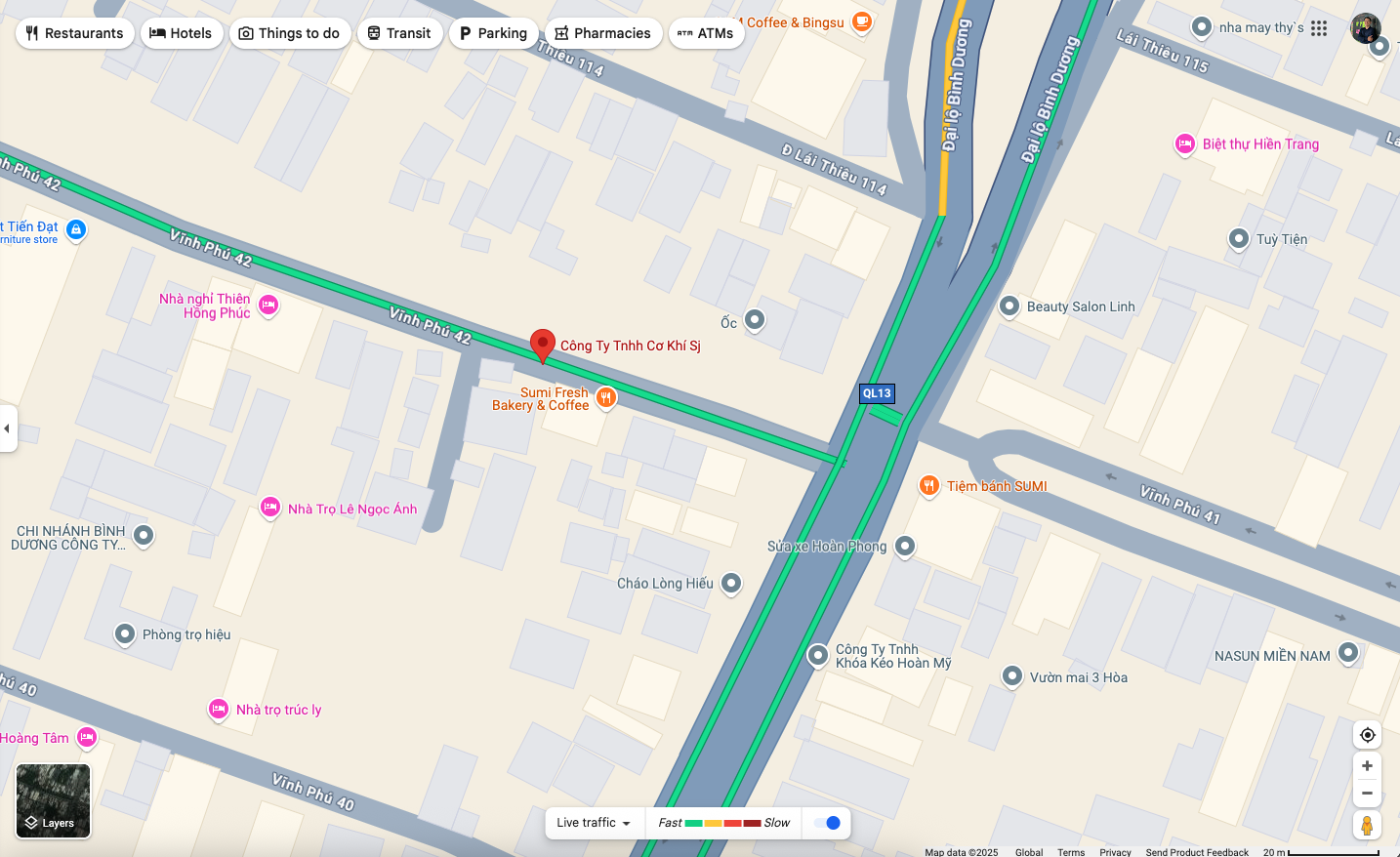

Get in Touch for Your CNC Turning Needs!

SJ CNC delivers precision-crafted CNC-turned parts for industries that require exceptional accuracy and efficiency. Contact us today to discuss your machining projects!

Reviews

There are no reviews yet.